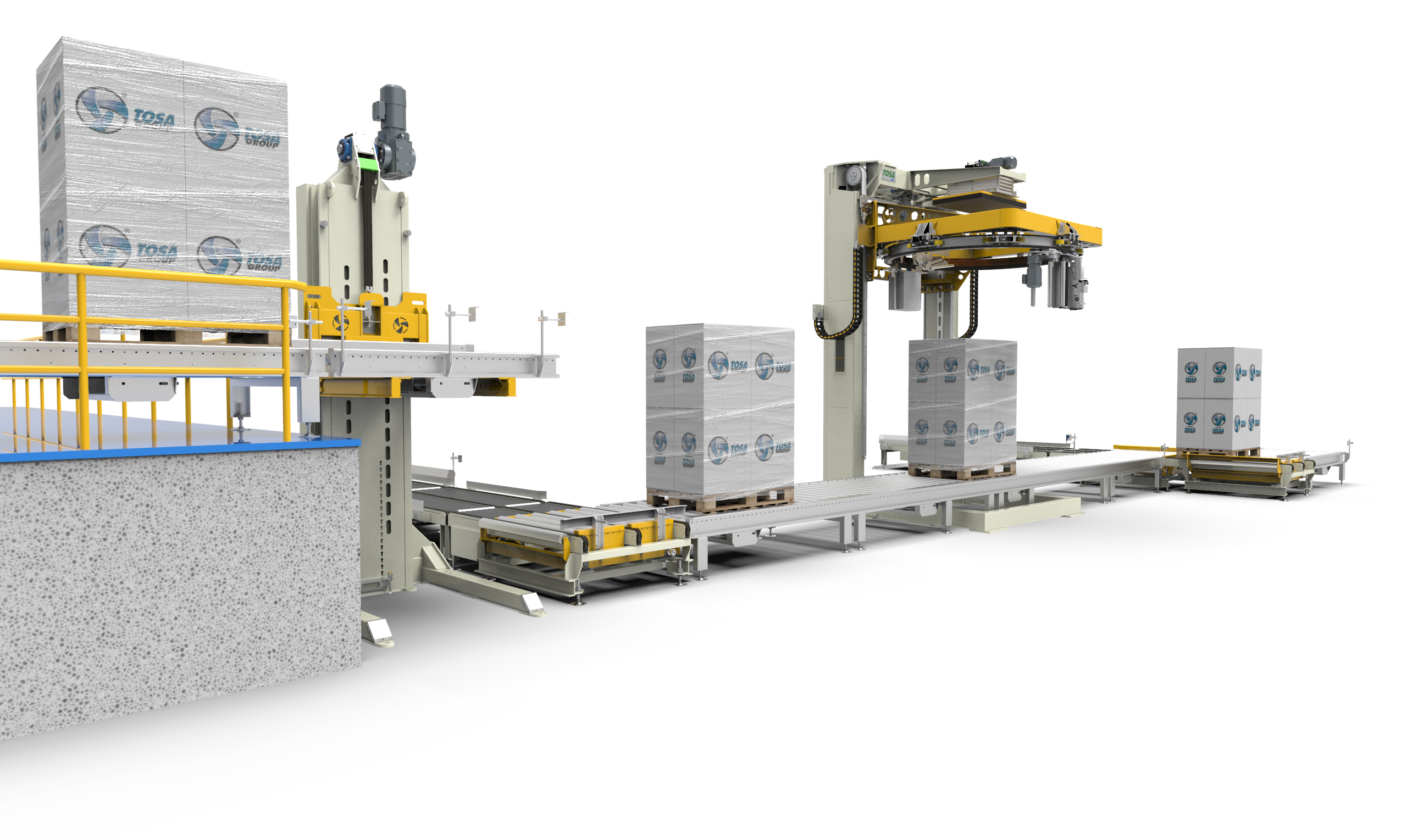

Tosa is a specialist of end of line. «To assure utmost product quality and integrity, the starting points must be the stability, the protection and the safety of the load», the Sales Area Manager Marco Cocino explains. «Choosing the best wrapping recipe is fundamental: it is developed by wisely mixing all right “ingredients”, optimizing wrapping costs.

Tosa machines allow setting up dedicated parameters for each product typology. The film pre-stretch percentage up to 400% permits to exploit at best its characteristics. The “strategic film positioning” because each product has different wrapping requirements, each area of the load needs a specific containment force and positioning the correct film quantity where necessary is extremely important. The cord film shrinkage allows anchoring the load to the pallet base, providing goods with the optimal stability.

The Smart Wrapping technology permits to optimize automatically the film distribution during wrapping cycle phases, actively checking its tension in the corners of the load. Finally, the application of cardboard corner protections avoids any damage in the product corners during transport and stocking».

Integration leads to efficiency

To make processing and line configuration phases more efficient and leaner, Cocino adds, «Tosa assures a perfect integration with the machines dedicated to upstream product processing phases, managing the information coming from the line through signal exchange, enhancing the efficiency of all processes and streamlining the various production and line configuration stages. Moreover, Tosa machines implement software for the fully automated changeover».

Tosa is committed to making processes safer. «The know-how developed along the years has permitted to maximize the process safety. The manufacturing philosophy “design for fail safe”, the positioning of motor and of lifting shaft placed on the ground avoid any potentially dangerous intervention at height. The configuration of the automatic film roll changeover that allows replacing the worn-out fill roll during the machine operation, without stops and in full safety.

Maintenance 4.0

Integral part of the design is the maintenance aspect. Our approach is maintenance 4.0 that combines Preventive Maintenance Smart Interface, graphic interface that allows guiding the operator in the planning and management of the preventive maintenance to assure constant excellence and durable performances, and Predictive Maintenance Smart Interface, graphic interface that monitors the real conditions of machine operations, warning through operational panel if are detected some symptoms that need small interventions that prevent future maintenance operations».