Tosa has embraced with conviction the environmental awareness issue. «Our company has been committed for years to the development of technologies aimed at maximising the sustainability degree of end-users’ products and processes», the Sales Area Manager Marco Cocino underlines.

«One of the cornerstones is certainly the manufacturing philosophy “Design for low maintenance”, which provides for the designing of each device to assure the minimum possible maintenance and to optimize time saving, cost saving, sustainability, safety and cleanliness.

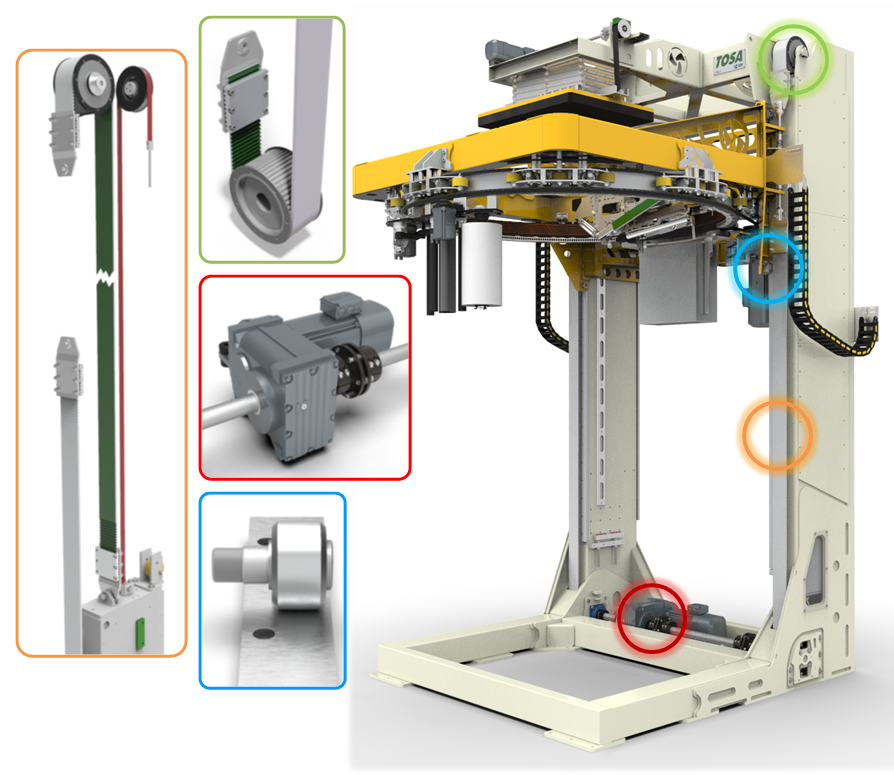

The elements in which the philosophy becomes concrete are the following: toothed belts, with very long service life, replacing lifting chains that need lubrication interventions; direct motors without using mechanical transmissions of the lifting group to avoid any maintenance or lubrication; sliding gears with lifelong pre-lubricated guide wheels.

Another in-house developed and patented technology is the automatic film roll changeover. The device is composed by sliding service carriages for the loading and the setup of the film roll to be changed; the operation is carried out by the operator during the machine operation, without stopping it, optimizing the plant’s production capacity».

How a smart data collection is set up

Tosa offers its support also in the processing scrap ambit. Tosa machines are equipped with a data collection system called «Smart Data Gathering System», Cocino adds. «It allows collecting and registering the following data for each processed pallet: cycle time, wrapping time, film consumption, effective average pre-stretching, load perimeter and dedicated wrapping programme. It allows establishing the data saving timing, the creation of a database inside the PLC and the filing in real time».

This is not all. «Our company is committed to the development of a software platform based on a Cloud, «named T-HYPOTALAMUS», that allows entering, analysing, consolidating and managing data and events of Tosa Group machines everywhere and at any time, from both mobile device and from PC. The analysis of these data allows managing and optimizing the performances of machines and production activities, maximising the TCO, understanding better the production flow and the most frequent anomalies and planning the preventive maintenance simply and intuitively».

Software and motors for energy saving

Finally, energy efficiency. «The use of Sew Eurodrive motors with IE3 (premium) efficiency class has been recently standardized to diminish CO2 emissions and the consumptions of industrial electric energy. To monitor the energy efficiency of processes with the final aim of energy saving for end-users, Tosa has developed software able to vary according to the line speed, then of the pallet flow that should be managed, the rotation speed of the machine to minimize energy and pneumatic consumptions», Cocino ends.