The 2023 edition of Cibus Tec, held in Parma at the end of October, ended with decidedly positive results, confirming itself as an international showcase of excellence for the most advanced and innovative technologies in the food & beverage sector, from raw material processing to packaging, with a focus on food safety, sustainability and energy efficiency.

Some figures at the end of the exhibition event

Over 40.000 professionals from Italy and abroad visited the exhibition, meeting 1.200 exhibitors presenting the most innovative Food Processing & Packaging solutions.

Thanks to the incoming programme organised at Cibus Tec, there were more than 3.000 Top Buyers of food & beverage companies from 80 different countries around the world, with more than 10.000 appointments recorded on the Business Agenda.

The balance of the Smart Packaging Hub at Cibus Tec 2023

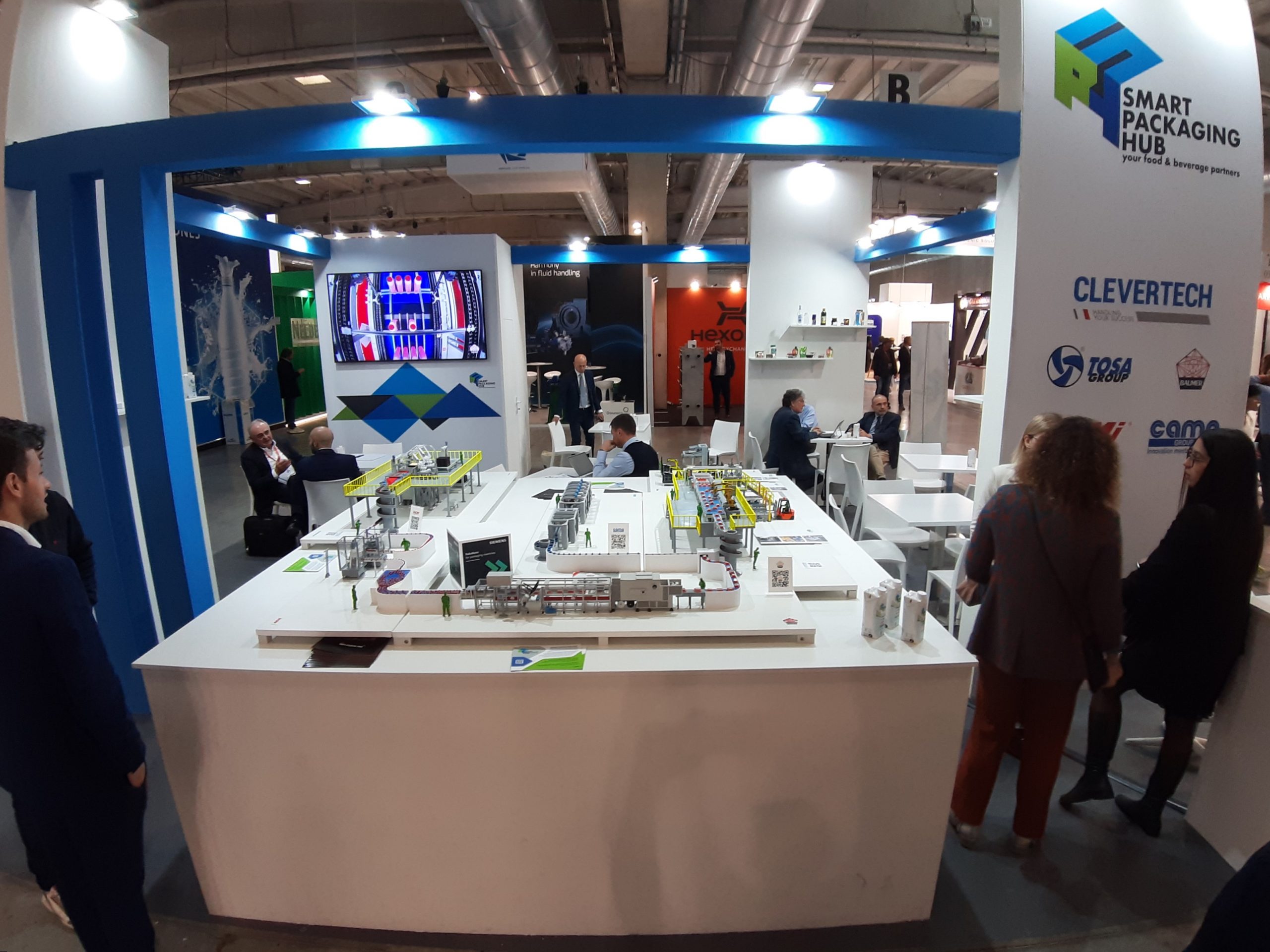

In the exhibition area of the trade fair dedicated to packaging technologies, the Smart Packaging Hub’s stand attracted the attention of several prospects, from both Italy and abroad, interested in the Hub’s activities as a meeting point where it is possible to exchange views with companies that are experts in each phase of the food & beverage packaging supply chain, capable of developing solutions with advanced and customisable technologies to meet the various automation requirements of a complete packaging line.

Baumer, Cama, Clevertech, Tosa and Zacmi, the five companies of the Smart Packaging Hub, met visitors at the Hub’s stand, offering their different skills in the packaging supply chain to respond with innovative and customised solutions to the different requests expressed by prospects.

In addition, the new projects that the Hub’s five partner companies presented for the fair intrigued and aroused the interest of visitors who stopped by the stand to learn about the details of the new technological solutions in line with the market trend, proposed by the Smart Packaging Hub professionals.

With these premises, let’s see how the balance of this edition of Cibus Tec was, expressed by the five companies of the Smart Packaging Hub.

Baumer

<<Our balance of the fair is positive>> explains Roberto Campagnini, Sales Manager of Baumer. <<We met several prospects from Italy, France, Northern Europe and South America, interested in our most innovative solutions to eliminate plastic film in secondary packaging in favour of cardboard packaging, to meet the market trend on sustainability>>.

<<At the show we presented ‘Rouge’ our latest wrap around machine project designed precisely to eliminate the use of plastic. This modular solution – continues Campagnini – aroused the interest of many visitors because, in addition to automatic format change, it can use different thicknesses, from corrugated to thin stretched cardboard, satisfying a variety of cardboard packaging requirements >>.

Cama

<< During this edition of Cibus Tec we had very positive feedback and were favourably surprised by the large number of international visitors>> explains Paola Fraschini, Marketing Manager of Cama Group. << There were several companies from different countries around the world interested in evaluating our solutions for automating their packaging lines or creating new ones>>.

<< We met several prospects from Italy and abroad, interested in our solutions for robotic top loading units and wrap around packaging machines. We have received enquiries in various sectors and for different product types. More and more companies have asked us for support in removing plastic from packaging, finding alternative solutions with cardboard to meet the market demand for sustainability>>.

<< Our new robotic monoblock machine project, presented at the exhibition, attracted the interest of several visitors. Its original system of circular rather than linear transport of the packages – concludes Paola Fraschini – in addition to reducing the footprint of the machine, it has made it possible to create separate shuttles attached to the conveyor belt, each of which gently holds the box by means of a vacuum system, designed not to scratch or ruin the package>>.

Clevertech

<<We saw a trade fair with an international flavour>> comments Luca Carollo, Business Development and Key Account at Clevertech. <<In addition to Italian and European food & beverage professionals, we also met prospects from South America, Central America and Asia. We are satisfied with the good results obtained>>.

<<Many companies, both Italian and foreign, were interested in learning about our automation solutions for the loading and unloading phases in autoclaves for the thermal treatment of packaged food products>>, continues Carollo.

<<The prospects we have met have shown interest in our automation solutions for the loading and unloading cycle for modern double-door autoclave systems, as they can significantly speed up the cycle, increasing productivity. This also decreases the temperature dispersion inside the autoclave to the benefit of energy efficiency and sustainability>>.

Tosa

<<We are satisfied with the results achieved during this fair, as we had the opportunity to meet several prospects from different countries around the world, interested in our end-of-line packaging automation solutions, downstream of palletising lines>> comments Marco Cocino, Sales Area & Marketing Manager at Tosa Group.

<<About 70% of the contacts we made were from foreign companies, mainly from the US, South America and Asia, and the remaining 30% were contacts from Italian and European companies>>.

<<The prospects we met were interested in learning about our fully automatic wrapping machines and on how we can meet their needs in terms of performance and flexibility in managing the wrapping processes of loads on various pallet formats, conveyed by several palletising lines>>, continues Cocino.

<< Particular attention was paid to the degree of quality and reliability of our wrapping machines, which can both meet the need to comply with the Eumos regulations regarding the stability of the load transported on trucks, and to fall within the tolerances of the sensor systems of automated warehouses in logistics companies. Our technologies answer to both of these demands>>.

<<The companies we met also asked for our support in finding alternative solutions to the use of plastic film to wrap palletised loads, in favour of a more sustainable approach>>.

<<During the meetings with prospects – continues Cocino – we carefully examined their needs in order to propose concrete and targeted solutions, such as the two new wrapping machine projects that we presented for the exhibition and which generated much interest.

The first project is ‘Cai Lun Hybrid’, our innovative wrapping machine that can work with both plastic film and kraft paper rolls, guaranteeing maximum flexibility for the customer. It is an eco-friendly alternative, although to match the containment performance of the load wrapped with stretch film, more kraft paper must be used in the wrapping cycle.

The second project is ‘Juracàn’, a rotating ring wrapping machine featuring an all-new four supports structure. It uses plastic film with the possibility to be equipped with automatic film roll changeover, ensuring high productivity. It is a competitive solution designed to meet the demands for performance and flexibility>>.

Zacmi

<<Since the last edition in 2019, Cibus Tec has once again confirmed itself as a successful event at international level. Our objectives were met and we drew a positive balance>> comments Laura Fulcini, Marketing Manager of Zacmi.

<< We received visits not only from our historical customers, but also from new companies interested in our automation solutions for the filling and seaming of food products, with interesting proposals to be developed according to customer requirements>>.

<<The companies we have met – continues Laura Fulcini – have also shown interest in our automatic washing solution for filling and seaming machines, to comply with hygiene and health regulations. This automatism avoids machine downtime for manual cleaning when production changes have to be made. This eliminates a manual process and increases productivity>>.

<<We had 50% contacts with Italian companies and the remaining 50% with European prospects and from different countries of the world – explains Laura Fulcini – Among the European visitors interested in our solutions, we met Spaniards, Portuguese, Germans and French. Among non-European countries, we had contacts with prospects from the United States, more from South America, and finally from Asia, particularly China>>.

<<Among the visitors, the ‘Synchronised Group’ – concludes Laura Fulcini – which we presented at the trade fair, aroused great interest. It is a technologically advanced, high-performance project. It consists of a 60 piston filler with a vertical valve for filling liquid and viscous product with solid parts, which works in synchrony with a 12-head seamer. The ‘Synchronised Group’ fills and seals tinplate and aluminium cans at a speed of up to 1.600 pieces per minute>>.